The Expansion of the Haven of Hope Hospital Project is to meet the rising service demand from the increasing and aging population. The scope includes construction of a New Block for the re-provision of 116 infirmary beds, the provision of 160 additional beds as well as the accommodation of a Day Medical and Rehabilitation Centre & an Integrated Carers’ Support Centre and the construction of the link bridges between the New Block and the existing Main Block.

The New Block is built with a unique design concept- ‘resort feel’, and with an aim to blend in with the surrounding landscape harmoniously. The New Block is designed in a way to align with the mission of HHH, “to provide holistic and quality health care service based on the love of Christ, professional excellence and progressive attitudes through which to witness the Christian Gospel; and solemnly care and respect every individual’s life, helping patients and their families to face diseases, suffering and even death with dignity and peace.”

Green Features

Site Aspects

- Air and noise pollution control plus regular air monitoring is conducted using Air Sensitive Receivers. By comparing the information from the baseline monitoring report, the air pollutants emitted and noise generated in the project site is effectively mitigated (SA11)

- Environmental Management plan (an ISO 14001 programme) is set up and implemented with regular inspection. Environmental Management & Audit Report is submitted in a monthly basis to ensure all environmental aspects identified are taken into account when implementing the Plan (SA 10)

- Water pollution is minimized through an effective treatment system with monthly sampling to authorized testing lab on pH value, Suspended Solids (SS) and Chemical Oxygen Demand (COD) to ensure proper treatment of wastewater (SA 13)

Materials Aspects

- All the materials for temporary works such as formwork, hoarding and walkways are the timbers produced in forest with certificates issued by forest sustainable council (FSC) or reused timber. At least 50% wooden building materials for permanent structure are FSC timbers to ensure the sustainability of forest ecosystem (MA P1, MA 6).

- Non-CFC based refrigerants are used in all Heating, Ventilation and Air Conditioning (HVAC) and refrigeration system to minimize the effect on ozone depletion. (MA P2 – material submission/purchasing stage now)

- At least 20% of the raw building materials used are from the region that is within 800km from the project site to minimize the carbon emission during transportation (MA 9).

Energy Use

- All design and equipment of building services system such as air-conditioning installation, lighting installation, electrical installation as well as lift and escalator installation and major outfitting works are strictly complied with Building Energy Codes to ensure the energy consumption is minimized. (EU P1: Partially materials submission, partially not yet started and partially purchasing stage)

- All system, equipment and components shall undergo testing and commissioning to investigate the overall impact on energy use and indoor environmental quality and hence, providing opportunities for future improvement (EU10: estimate to be done before OP)

- Metering facilities are incorporated into the electricity system of building services such as air-conditioning system in common places or public areas for metering and monitoring the electricity usage and providing opportunities for future improvement on electricity usage. (EU12)

Water Use

- All the sanitary fittings and devices in washrooms, kitchens or pantries, etc. are complied with the maximum flow rates standards to avoid wastage on water consumption in the early planning stage. (WU p2)

- Water quality survey of portable water based on the standards stated by WSD shall be carried out by authorized testing to ensure that the portable water contains no harmful heavy metals or toxicants or pollutants. (WU P1 – estimated to be done before OP)

Indoor Environmental Quality

- Minimum ventilation performance shall achieve at least 30% increase from the minimum ventilation rate and perform 8-hour baseline measurement for outdoor air pollutants including respirable suspended particulates (RSP), carbon monoxide (CO), ozone (O3) and nitrogen dioxide at initiation stage and achieve good class in the Indoor Quality Certification Scheme (IEQ P1)

- Before occupancy, flush out or bake out and replacement of all filters should be performed to ensure air pollutants created during construction phase are flushed out. (IEQ5)

Story

The Project has employed the following tactics with an aim to go “green”:-

Site Management Plan

- To ensure that all construction site personnel will avoid and/or minimise the on-site generation of construction & demolition materials;

- To estimate the quantities of various types of wastes and their duration of generation;

- To reuse and recycle the construction & demolition and excavated materials, and to keep the construction site clean and tidy;

- To propose proper methods of handling, storage, transportation and disposal of construction & demolition wastes generated from the Project;

- To ensure proper implementation of the trip ticket system (TTS)

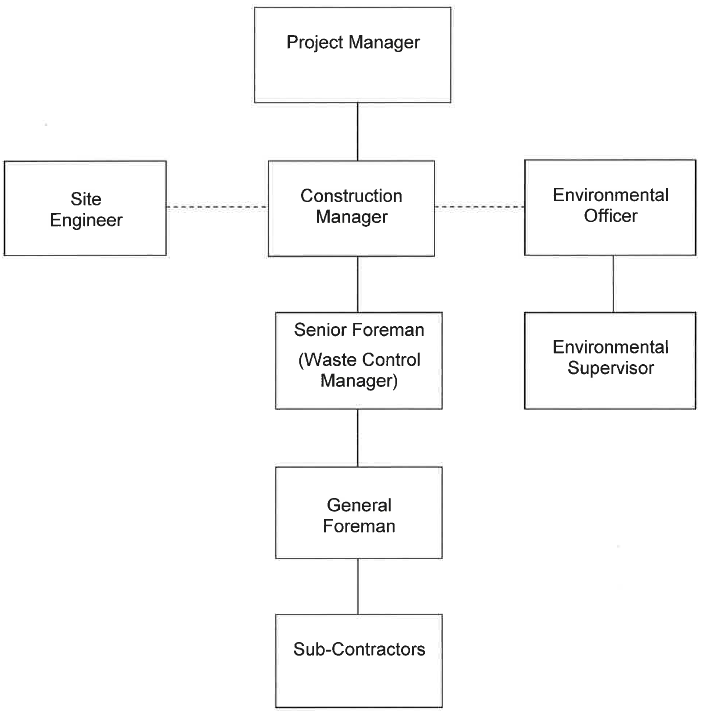

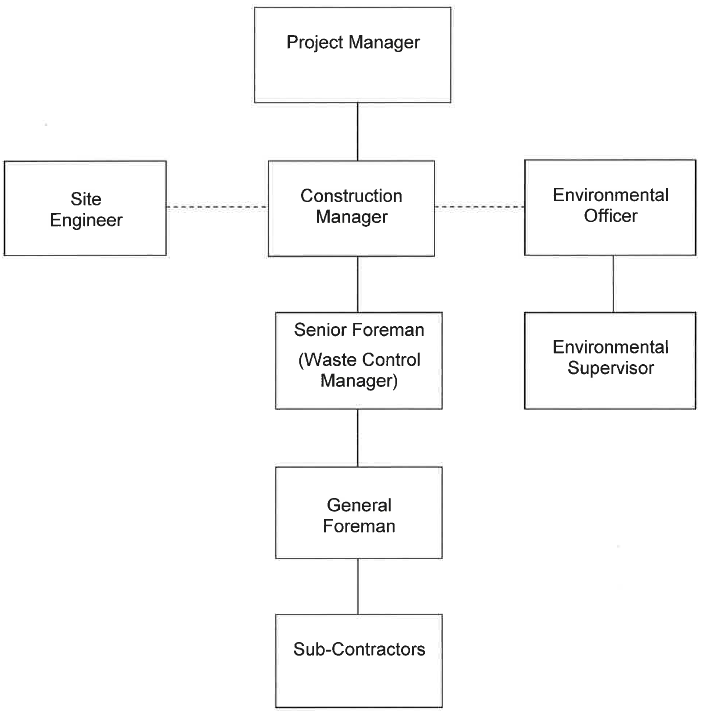

Environmental Supervision

The project has a very well Waste Management Organisation:

Construction Manager

- To supervise and coordinate project team and sub-contractors for the construction works to meet the waste management requirements;

- To be the point of contact for day-to-day waste management issues;

- To carry out immediate action to rectify any non-compliance of environmental requirements as well as to handle any complaints received from the public.

Environmental Officer

- To review the Site Management Plan for implementation of TTS and ensure works are executed in accordance to the Plan;

- To monitor the performance of the Waster Manager in overseeing the TTS;

- To check and ensure any polluting or potentially polluting situations are promptly rectified.

Environmental Supervisor

- To assist Environmental Officer

- To attend weekly environmental walk and environmental meeting;

- To supervise and promote the execution of environmental protection works on site;

- To prepare the construction & demolition waste disposal records and keep adequate and proper records for inspection.

Procedures for Waste Disposal

- All excavated materials will be sorted at the area on ground floor to separate the construction & demolition materials for public fill or landfill. All waste materials for recycle and reuse will be temporarily stored before disposal;

- A trip ticketing for recording the disposal of construction & demolition materials from the site will be implemented;

- The truck driver will have the stamp from the responsible person of the designated location receiving the disposal materials;

The trip ticket will be returned to the Waste Control Manager with the transaction record.